HDPE Granules

Price 30 INR/ Kilograms

HDPE Granules Specification

- Material

- HDPE (High Density Polyethylene)

- Hardness

- Rigid

- Form

- Granules

- Thickness

- Varies as per requirement

- Packaging Type

- Bags

- Usage & Applications

- Blow molding, Injection molding, Film production, Pipe manufacturing, Bottle and container production

- Type

- ABS

- Material Feature

- Easy Used

- Grade

- Industrial Grade

- Melting Point

- 126-135C

- Color

- Multi

- Warranty

- Yes

- Moisture Content

- <0.1%

- Flow Rate (MFI)

- ± 0.35 g/10 min

- Shape

- Cylindrical granules

- Odor

- Odorless

- UV Resistance

- Standard

- Storage

- Store in cool, dry place

- Contaminants

- Free from external contaminants

- Impurity Level

- Negligible

- Recyclability

- 100%

HDPE Granules Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Sample Available

- Yes

- Main Domestic Market

- Maharashtra

About HDPE Granules

HDPE Granules

|

Leading mfg/distributors & Pioneers in reprocess plastic industry, we offer HDPE (BL & MO) Granules such as Polypropylene Granule, High Density Polyethylene (HDPE) Granules, Low Density Polyethylene (LDPE), Acrylonitrile Butadiene Styrene (ABS ), Nylon 6 & 66 Granules, EVA Granules and many more items from India.

|

|

We offer the following

- HDPE (Blow) Natural 4001 Granules

- HDPE (Blow) Natural 4002 Granules

- HDPE (Blow) Natural 4003 Granules

- HDPE Black Pipe Granules

- HDPE (Blow) V Milky Granules

- HDPE (Blow) Blue Drum Granules

- HDPE (Moulding ) Black Granules

- HDPE (Moulding) Color Granules.

Versatile Applications

HDPE granules excel in an array of industrial applications, including blow molding, injection molding, film production, and the manufacturing of pipes, bottles, and containers. Their rigid structure and controlled melting point make them ideal for varied production requirements, delivering consistent results in diverse projects.

Quality Assurance and Purity

Produced with negligible impurities and less than 0.1% moisture content, these granules are free from external contaminants and feature standard UV resistance. Ensuring high durability and reliability, the granules promise superior end-product quality for manufacturers and suppliers thanks to strict quality control measures.

Responsible and Sustainable Choice

With 100% recyclability and an odorless profile, our HDPE granules support sustainable production goals. Their multi-color option and easy-to-use form further enhance manufacturing efficiency, contributing to environmentally responsible processes without compromising on quality or performance.

FAQ's of HDPE Granules:

Q: How should HDPE granules be stored for optimal quality?

A: HDPE granules should be kept in a cool, dry location, away from moisture and direct sunlight, to maintain their low moisture content and prevent contamination. Proper storage ensures material integrity for extended periods.Q: What manufacturing processes can utilize these cylindrical HDPE granules?

A: Our HDPE granules are suitable for blow molding, injection molding, film production, as well as pipe, bottle, and container manufacturing, due to their consistent form, melt flow rate, and rigidity.Q: When is it most beneficial to use HDPE granules with standard UV resistance?

A: These granules are ideal for products intended for moderate outdoor exposure, as their standard UV resistance helps minimize degradation and maintain product lifespan under normal environmental conditions.Q: Where are these HDPE granules commonly supplied and used?

A: Distributed, exported, and supplied throughout India, our HDPE granules are widely used by manufacturers, exporters, and importers involved in large-scale industrial and packaging applications.Q: What is the process for using HDPE granules in manufacturing?

A: HDPE granules are typically melted and molded through industrial processes like blow or injection molding, allowing them to be shaped into films, pipes, bottles, or various containers based on production needs.Q: What benefits do these HDPE granules offer over other materials?

A: These granules offer several advantages: they are rigid, easily processed, odorless, recyclable, and manufactured with high purity, making them a sustainable and reliable choice for modern industry.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Granules Category

Virgin HDPE Granules

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Type : ABS

Color : White

Weight : 25 Kg (typical packaging bag)

Grade : Industrial grade / Food grade (varies by product)

Hdpe Plastics Granules

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Type : ABS

Color : Multi

Weight : Depends on packaging

Grade : Industrial

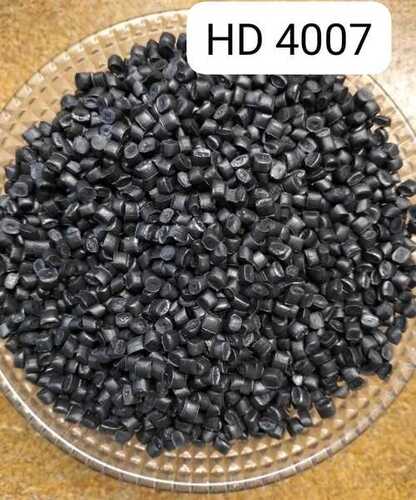

HDPE 4007 Granules

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Type : HDPE

Color : BLACK

Weight : 25 Kilograms (kg)

Grade : 4007

HDPE DRUM GRANULES

Price 78 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Type : HDPE

Color : BLUE

Weight : 25 Kilograms (kg)

Grade : 4004

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry