Hdpe Plastics Granules

Price 30 INR/ Kilograms

Hdpe Plastics Granules Specification

- Material

- HDPE (High Density Polyethylene)

- Hardness

- High

- Usage & Applications

- Blow Moulding, Injection Moulding, Film Production, Pipe Manufacturing, Packaging

- Thickness

- Customized

- Packaging Type

- Bag

- Form

- Granules

- Type

- ABS

- Material Feature

- Easy to use

- Grade

- Industrial

- Melting Point

- 120 - 140C

- Weight

- Depends on packaging

- Color

- Multi

- Warranty

- Yes

Hdpe Plastics Granules Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Sample Available

- Yes

- Main Domestic Market

- Maharashtra

About Hdpe Plastics Granules

Hdpe Plastics Granules

Clients can avail from us a quality assortment of HDPE/ Polypropylene Copolymer Plastic Granules (PPCP). These are widely used in the production of various plastic products and are offered as per the specific requirements of our clients. Further, the reprocessed plastic we offer to clients is offered at market leading prices.

*We supply granules to so many leading Mfg.

Leading Mfg/distributors & Pioneers in reprocess plastic industry, We offer Hdpe Plastics Granules such as Polypropylene Granule, High Density Polyethylene (HDPE) Granules, Low Density Polyethylene (LDPE), Acrylonitrile Butadiene Styrene (ABS ), Nylon 6 & 66 Granules, EVA Granules and many more items from India.

We offer the following

- HDPE (Blow) Natural 4001 Granules

- HDPE (Blow) Natural 4002 Granules

- HDPE (Blow) Natural 4003 Granules

- HDPE Black Pipe Granules

- HDPE (Blow) V Milky Granules

- HDPE (Blow) Blue Drum Granules

- HDPE (Moulding ) Black Granules

- HDPE (Moulding) Color Granules.

Versatile Industrial Applications

HDPE Plastics Granules are engineered for diverse uses across the manufacturing sector. Whether needed for blow moulding, injection moulding, film production, pipe manufacturing, or packaging, these granules provide robust performance and consistent results. Their high purity and strength make them a preferred choice for industries seeking uncompromising quality and reliability.

Quality You Can Trust

Manufactured and marketed by reputable suppliers and exporters in India, our HDPE granules adhere to strict quality standards. With a 99% purity rate, low ash and moisture contents, and a warranty included, customers can be confident in both material performance and supplier credibility.

FAQ's of Hdpe Plastics Granules:

Q: How are HDPE Plastics Granules processed for industrial use?

A: HDPE Plastics Granules are processed using techniques such as blow moulding, injection moulding, and film production. Depending on your requirement, you can choose either virgin or recycled grades, both offering easy handling and excellent material properties.Q: What are the main benefits of using HDPE granules in manufacturing?

A: HDPE granules provide high purity, hardness, and odorless characteristics, making them ideal for industries needing durable and versatile materials. They are easy to use, customizable in thickness, and suitable for applications like pipe manufacturing and packaging.Q: When should I opt for recycled HDPE granules instead of virgin ones?

A: Consider recycled HDPE granules when sustainability and cost-effectiveness are priorities without compromising necessary quality. For applications requiring ultra-high purity and performance, virgin granules are recommended.Q: Where are these HDPE granules commonly supplied from?

A: These HDPE granules are sourced from reputed manufacturers, exporters, and suppliers across India. The established distribution network ensures availability for both domestic and international buyers.Q: What is the grade and melting point of these HDPE granules?

A: The granules are of industrial grade, tailored for heavy-duty manufacturing. They offer a melting point range between 120C and 140C, suitable for various high-temperature processing applications.Q: How should the granules be stored to maintain their quality?

A: HDPE granules should be kept in their original, sealed bags and stored in a dry, cool environment to prevent absorption of moisture and contamination, thus preserving their low moisture content and high purity.Q: What warranty is provided on these HDPE granules?

A: A manufacturer's warranty is provided, ensuring the material meets advertised quality standards and reassuring buyers about the reliability and performance of the granules.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Granules Category

Virgin HDPE Granules

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : White

Type : ABS

Material Feature : Easy to use

Melting Point : 120135C

HDPE DRUM GRANULES

Price 78 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Color : BLUE

Type : HDPE

Material Feature : DRUM

Melting Point : 180

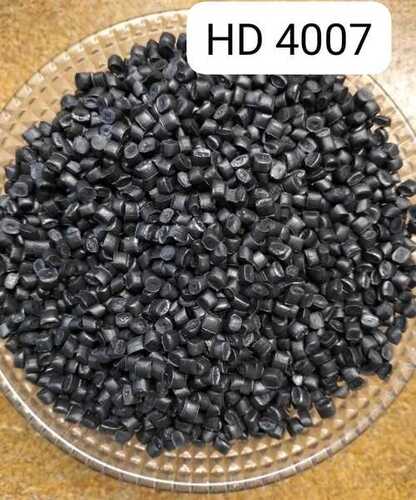

HDPE 4007 Granules

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Color : BLACK

Type : HDPE

Material Feature : Recyclable

Melting Point : 120135 deg C

Hdpe Crates Regrind

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Blue

Type : ABS

Material Feature : Easy to use

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry