Virgin HDPE Granules

Price 30 INR/ Kilograms

Virgin HDPE Granules Specification

- Hardness

- Shore D 60-70

- Form

- Granules

- Usage & Applications

- Injection molding, blow molding, film extrusion, containers, pipes, cables

- Thickness

- Subject to application

- Packaging Type

- Bag

- Material

- HDPE (High Density Polyethylene)

- Type

- ABS

- Material Feature

- Easy to use

- Grade

- Industrial grade / Food grade (varies by product)

- Melting Point

- 120-135C

- Weight

- 25 Kg (typical packaging bag)

- Color

- White

- Warranty

- Yes

- Processing Temperature

- 160-250°C

- Odor

- Odorless

- Chemical Resistance

- Excellent

- Impact Strength

- High

- UV Resistance

- Medium

- Moisture Absorption

- Very Low

- Surface Finish

- Smooth

- Elongation at Break

- 20-30%

Virgin HDPE Granules Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Sample Available

- Yes

- Main Domestic Market

- Maharashtra

About Virgin HDPE Granules

High Density Polyethylene (HDPE) Granules

With the support of our experts and sophisticated in-house facilities, we have been able to offering Virgin HDPE Granules that are processed under the guidance of skilled professionals. The offered HDPE granule are accredited by clients for their good low temperature toughness and other chemical properties. Clients avail these Virgin HDPE Granules for their broad applications in making in bottles, food wrapping materials, containers, plastic bags, etc.

Following are the applications of High Density Polyethylene (HDPE) Granules:

- Containers

- Shampoo bottle HDPE ( Black natural & colored granules)

- Chemical drums

- Jerricans

- Carboys

- Toys

- Picnic ware

- Household and kitchenware

- Cable insulation

- Carrier bags

- Food wrapping material

We offer the following:

- HDPE (Blow) Natural 3001 Granules

- HDPE (Blow) Natural 3002 Granules

- HDPE (Blow) Natural 3003 Granules

- HDPE Black Pipe Granules

- HDPE (Blow) V Milky Granules

- HDPE (Blow) Blue Drum Granules

- HDPE (Moulding ) Black Granules

- HDPE (Moulding) Color Granules.

Exceptional Mechanical and Chemical Properties

Virgin HDPE Granules stand out for their high impact strength and excellent chemical resistance, making them ideal for a range of industrial and food-related applications. The material's low moisture absorption and smooth finish enhance its durability and aesthetics, while its odorless nature ensures product safety and quality. These properties are essential for reliable long-term performance in demanding environments.

Versatile Processing Abilities and Uses

With a processing temperature window of 160-250C and a melting point of 120-135C, HDPE granules are tailored for diverse manufacturing techniques such as injection molding, blow molding, and film extrusion. This versatility allows for the creation of a wide range of products, including containers, pipes, cables, and films, satisfying various industry requirements.

FAQ's of Virgin HDPE Granules:

Q: How are Virgin HDPE Granules typically processed for manufacturing?

A: Virgin HDPE Granules are processed using methods like injection molding, blow molding, and film extrusion. These techniques work well with HDPE due to its optimal melting point (120-135C) and broad processing temperature range (160-250C), ensuring precise shaping and reliable production outcomes.Q: What products can be made using these granules?

A: These granules are perfect for manufacturing injection molded items, blow-molded containers, extruded films, pipes, and cables. Their excellent chemical resistance and mechanical strength make them suitable for both industrial and food-grade applications, depending on the chosen grade.Q: When should I opt for industrial grade versus food grade HDPE granules?

A: Industrial grade HDPE granules are suitable for products not in contact with food, such as pipes and cables. For applications involving food storage or packaging, choose food grade HDPE, which adheres to stringent safety standards and regulatory requirements.Q: Where can I purchase Virgin HDPE Granules in India?

A: You can buy these HDPE granules from authorized distributors, exporters, importers, manufacturers, and suppliers across India who offer a variety of grades and packaging options, typically supplied in 25 kg bags.Q: What are the key benefits of using these granules for manufacturing?

A: Key benefits include high impact and chemical resistance, low moisture absorption, ease of processing, excellent surface finish, and medium UV resistance. Furthermore, they are odorless and offer consistent quality, resulting in durable, safe, and efficient end products.Q: How does the UV resistance of these HDPE granules affect outdoor applications?

A: With medium UV resistance, these HDPE granules provide reasonable protection against sunlight, but for prolonged outdoor use or harsh environments, additional UV stabilizers may be recommended for maximum longevity and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Granules Category

HDPE Granules

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Type : ABS

Color : Multi

Material Feature : Easy Used

Grade : Industrial Grade

HDPE DRUM GRANULES

Price 78 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Type : HDPE

Color : BLUE

Material Feature : DRUM

Grade : 4004

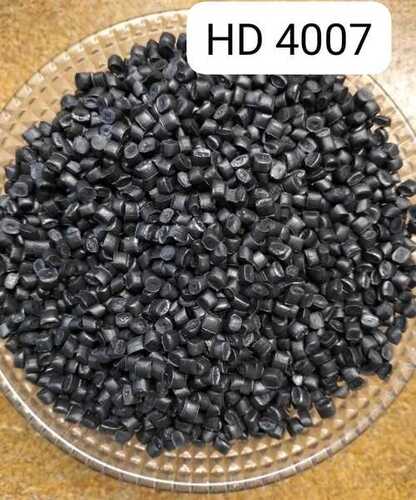

HDPE 4007 Granules

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Type : HDPE

Color : BLACK

Material Feature : Recyclable

Grade : 4007

Hdpe Crates Regrind

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Type : ABS

Color : Blue

Material Feature : Easy to use

Grade : Chemical

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry