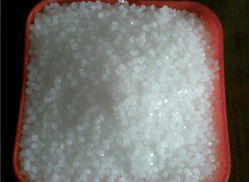

Polycarbonate Granules

Price 30 INR/ Kilograms

Polycarbonate Granules Specification

- Form

- Granules

- Material

- Polycarbonate (PC)

- Packaging Type

- Bag

- Hardness

- Shore D 75-80

- Usage & Applications

- Injection molding, extrusion, automotive components, electrical housings, medical devices, optical disks

- Thickness

- Can be customized as per requirements (granular form)

- Type

- PA

- Material Feature

- Easy Usable

- Grade

- Industrial/Commercial grade

- Melting Point

- 230C 260C

- Weight

- 25 kg (standard packaging bag)

- Color

- Glss

- Warranty

- Yes

Polycarbonate Granules Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Cash Advance (CA), Cheque

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- Maharashtra

About Polycarbonate Granules

Polycarbonate Granules

Focused on technological up-gradation, dynamism and innovation, we are moving ahead by maintaining timeliness in delivering a wide gamut of Polycarbonate Granules that are known for thermal stability, low melting point, high stiffness, chemical & physical properties and heat & temperature resistance. Processed utilizing modern processing techniques in compliance with set industry standards, this plastic granule is used to manufacture electrical switches, medical instruments, water bottles, appliances housing & components. Clients can avail the Polycarbonate Granules in different quantities at affordable prices.

Following are the applications for which our products are used:

- Automotive Components

- Appliances Housing and Components

- Lenses

- Housings for headlamps

- Rear lamps

- Signal lightings

- CDs

- Switches

- Plugs

- Sockets

- Circuits

- Breakers

- Lenses for indoor and outdoor lightings

- Medical instruments

- Water bottles

- Roofing systems

- Corrugated & multi-wall sheet

- Sun glasses

- Ski goggles

- Spectacles

- Lenses

- Visors

- Safety helmets

- Textile bobbins

- Optical lenses

LDPE Granules

-

LDPE Natural (Next to Virgin) 6001 Granules

-

LDPE Natural (Semi virgin) 6002 Granules

-

LDPE Natural (Plant Waste) 6003 Granules

Exceptional Impact Strength and Clarity

Our polycarbonate granules boast high impact strength while maintaining excellent transparency, making them ideal for applications demanding both toughness and a clear appearance. The stable glass-like finish supports both aesthetic and functional needs in sectors like automotive, electronics, and medical devices.

Versatile and Efficient Processing

With excellent flow properties and customizable thickness, these granules ensure efficient and consistent processing for both injection molding and extrusion applications. This versatility allows manufacturers to produce components with complex designs and fine details with ease.

Reliable Safety and Environmental Features

Choose from flame retardant options for enhanced safety and benefit from the material's recyclability. Moderate to high UV resistance, paired with a low moisture absorption rate, contributes to product longevity and environmental responsibility, supporting a range of indoor and outdoor usage scenarios.

FAQ's of Polycarbonate Granules:

Q: How are polycarbonate granules processed in manufacturing applications?

A: Polycarbonate granules are mainly processed using injection molding and extrusion techniques due to their excellent flow properties. Their easy usability allows for efficient molding into complex shapes and detailed parts, making them a preferred choice for automotive components, electronic housings, medical devices, and optical disks.Q: What benefits do these polycarbonate granules offer compared to other plastic types?

A: These granules offer high impact strength, impressive heat deflection temperature (130C - 140C), superior transparency, and can be customized with flame retardant and UV-resistant additives. Their recyclability and low moisture absorption enhance their appeal for sustainable, high-performance applications.Q: When should I opt for flame retardant grades of polycarbonate granules?

A: Flame retardant grades are recommended when safety standards demand fire resistance, such as in electrical housings, automotive interiors, or areas where the material might be exposed to ignition sources. These options help ensure compliance with industry regulations and improve product safety.Q: Where can these polycarbonate granules be applied?

A: These granules are widely used in industries such as automotive (for durable, clear parts), electronics (in housings and components), healthcare (for medical devices), and the optical sector (for data storage disks), offering versatile utility in both indoor and outdoor environments.Q: What is the optimal storage process for polycarbonate granules?

A: To maintain quality, store granules in sealed bags (typically 25 kg), away from moisture and direct sunlight. Even with low moisture absorption, proper storage ensures consistent processing and mechanical properties during manufacturing.Q: How does the recyclability of these granules benefit manufacturers and the environment?

A: The ability to recycle polycarbonate granules allows manufacturers to minimize waste, reduce material costs, and support sustainability initiatives. Recycled material can often be reintroduced into the production cycle without compromising quality for many applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Plastic Granules Category

Ethylene Vinyl Acetate (EVA) polymer

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Warranty : Yes

Type : PA

Color : Grey

Material Feature : Low

Recycled Plastic Granules

Price 30 INR / Kilograms

Minimum Order Quantity : 550 Kilograms

Warranty : Yes

Type : PA

Color : White

Material Feature : Low

Polyethylene Granules

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Warranty : Yes

Type : ABS

Color : Multi

Material Feature : Easy to use

HD Granule

Price 30 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Warranty : Yes

Type : PA

Color : White

Material Feature : Easy melted

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry